南通辊筒输送线,南通滚筒输送线,南通滚筒线的内置式阻尼辊筒内有一套齿轮行星传动机构,辊筒内壁右端有一内齿具结,与三个行星轮啮合,辊筒旋转时,内齿轮通过行星轮带动中轮旋转,中心轮的左侧装有两个制动块,制动块的一端通过销轴铰支在中心轮上,制动块可以围绕销轴摆动;另一端则通过弹簧与中心轮相联,弹簧的拉力使得制动块平时保持收缩状态。当输送物料的滑行速度增大时,制动辊的转速也增大,通过行星机构的增速作用,中心轮的转速也增大,直至产生的离心力足以使两制动块克服弹簧拉力绕销轴由外摆动,与制动辊的内壁接触挤紧,产生制动作用,从而使得输送物的速度逐渐减少。当速度减至设定值时,制动块也在弹簧力的作用下复位,失去制动作用。

There is a set of gear planetary transmission mechanism in the built-in damping roller of the roller conveying line. There is an inner tooth on the right end of the roller inner wall, which is meshed with three planetary wheels. When the roller rotates, the inner gear drives the middle wheel to rotate through the planetary wheel. The left side of the center wheel is equipped with two brake blocks. One end of the brake block is hinged on the center wheel through the pin shaft, and the brake block can swing around the pin shaft; the other end The spring is connected with the central wheel, and the tension of the spring makes the brake block keep contracting at ordinary times. When the sliding speed of the conveying material increases, the rotating speed of the brake roller also increases. With the increase of the speed of the planetary mechanism, the rotating speed of the central wheel also increases until the centrifugal force generated is enough to make the two brake blocks overcome the spring tension and swing around the pin shaft from the outside, contact and squeeze with the inner wall of the brake roller to produce the braking effect, so as to gradually reduce the speed of the conveying material. When the speed is reduced to the set value, the brake block also resets under the action of the spring force and loses the braking effect.

在设计过程曾考虑过采用外置式阻尼辊筒,但这种外置式阻尼辊筒置在公司中用的不少,而且有一定的缺陷,外置的稳定性是它的一个最不稳定的因素。所以综上原因,采用内置式阻尼辊筒。内置式阻尼辊筒实用性和简易性相对提高了不少。更加适用于大多数的重力辊道输送线的阻尼装置。

In the design process, the external damping roller has been considered, but this external damping roller is used in many companies, and has some defects. The external stability is one of the most unstable factors. So to sum up, the built-in damping roller is used. The utility and simplicity of the built-in damping roller are improved relatively. It is more suitable for the damping device of most gravity roller conveyor lines.

内置式阻尼辊筒的要核心部件是行星轮系,根据重力辊筒输送线中的传动辊的长短,需要多少规格的阻尼辊筒可以设计生产,所以内置式的阻尼辊筒实用性很高。总体配置就是合理安排各部件位置和联接关系,确定动力的传动路线,与传动辊的联接关系,使得整个阻尼装置的工艺路线流畅合理,并且便于使用调整和维修。

The key component of the built-in damping roller is the planetary gear system. According to the length of the transmission roller in the gravity roller conveying line, how many specifications of damping roller can be designed and produced? Therefore, the built-in damping roller has high practicability. The overall configuration is to reasonably arrange the position and connection relationship of each component, determine the transmission route of the power and the connection relationship with the transmission roller, so that the whole process route of the damping device is smooth and reasonable, and easy to use, adjust and maintain.

阻尼辊筒的整体设计:

Overall design of damping roller:

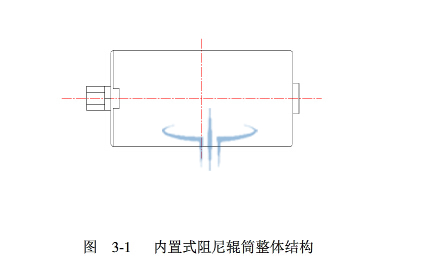

内置式阻尼辊筒作业一种简易和实用的新型阻尼装置,其通用性大。下面是其整体设计;如图

The built-in damping roller is a simple and practical new damping device, which has great universality. The following is the overall design; as shown in the figure

在左侧安装一个探头,用于安装在重力辊道上。整体结构如图,整体结构用于安装于传动辊中,来控制传动辊的速度。至于行星轮系。至于行星轮系,制动块等装置安装在这个整体的结构当中。因为该内置式阻尼辊筒的操作比较简单,为了使得机械安装方便,这里将阻尼辊筒与重力辊道连为一体。

Install a probe on the left side for installation on the gravity roller table. The overall structure is shown in the figure. The overall structure is installed in the driving roller to control the speed of the driving roller. As for planetary gear trains. As for planetary gear train, brake block and other devices are installed in the overall structure. Because the operation of the built-in damping roller is relatively simple, in order to make the mechanical installation convenient, the damping roller and the gravity roller are connected as one.